In March, we received a unique request from a major European online furniture retailer. They wanted a very durable and high-quality sintered stone (ceramic) table for their outdoor furniture range, but they also needed this new product line to pass a drop test at a height of 90cm, and all tables had to survive the drop test with no damage. It seemed impossible because the sintered stone (ceramic) material is by nature very brittle.

The tables we designed weighed over 70kg including package, which led to a significant question: How could we guarantee that such a heavy and brittle table top would survive a drop from nearly a meter high? To put it bluntly, we were being challenged in relation to engineering and packaging!

Our Solution: Unique Packaging Solutions and a Daring Stand

Our engineer team went to work after acknowledging the urgency and difficulty of the situation. We did not just deliver what they asked for. We exceeded their request by creating two custom tabletop models and a total packaging solution. Our approach was based on two principles:

- Maximum Cushion – We used 5cm thick high density foam, at the bottom of the tabletop, and filled in every void to ensure it would not budge during transport.

- Structural Support – We used 2 custom MDF (medium density fiber board) protective sleeves for the most vulnerable ends of the sintered stone tabletop to provide maximum structural support, where it was most needed.

In April, the client’s QC manager came to witness the test. We began with a smaller version of the 900x 1600mm table, even though its weight of 54kg was a challenge.

After 6 detrimental drops from 90 cm height, we opened the packages, and confirmed that it was a total success – the sintered stone tabletop was completely intact, with only the MDF corner protectors with loose screws and some cracks.

The Outcome: From Successful Test to Full Container Shipment

After our initial success the client’s QC manager challenged us to take on our biggest challenge yet – the 1.8m x 0.9m table, weighing in at a whopping 72kg! Again we repeated the drop testing process and the table passed with flying colours.

The client’s QC manager was very impressed – stating she had never seen a product packaged so well. This successful test was not only a pass, it was a positive endorsement of our quality practices and problem solving abilities.

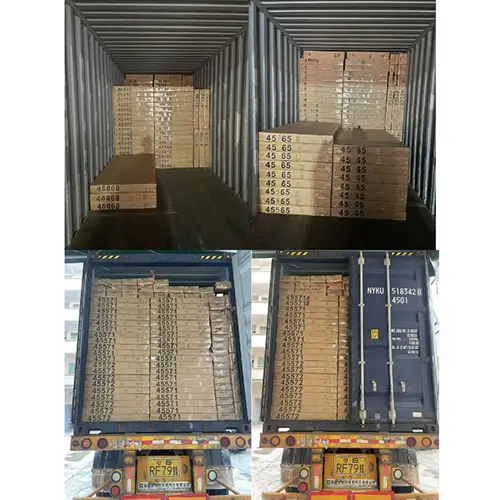

On May 10th the client ordered a 40-foot HQ container loaded with 310 sintered stone tables without hesitation. We manufactured the order and shipped it in early July. As the loading pictures demonstrate, we executed successfully the large project and packed efficiently. Every one of the 310 pieces was packed securely to commence its long journey.

For us it was not just business, it was partnership as we believe if our customers win, we win. This case study was an example of how our attention to detail and quality practices can help a client overcome a significant barrier and succeed in the marketplace.

So are you ready for your next sintered stone table project with us?

If your company has extremely specific or challenging customization requirements, we can help. As a trusted sintered stone table manufacturer, we are here and ready to help you with the smartest solution to realise your vision.

Contattateci and let’s discuss your sintered stone table project.