Extendable Tempered Glass Dining Tables by Astonisa, the Leading China Manufacturer

1. 90% of glass dining tables are extended from both ends

2. Oval shape, rotate to expand

Glass table edge detail

Even though there are many edge options, we mainly manufacture flat polished edges for our glass tables, characterized by clean lines and a smooth, glossy appearance. There is a 45° bevel on the top and bottom edges of the glass, which softens the sharpness and provides a minimalist aesthetic.

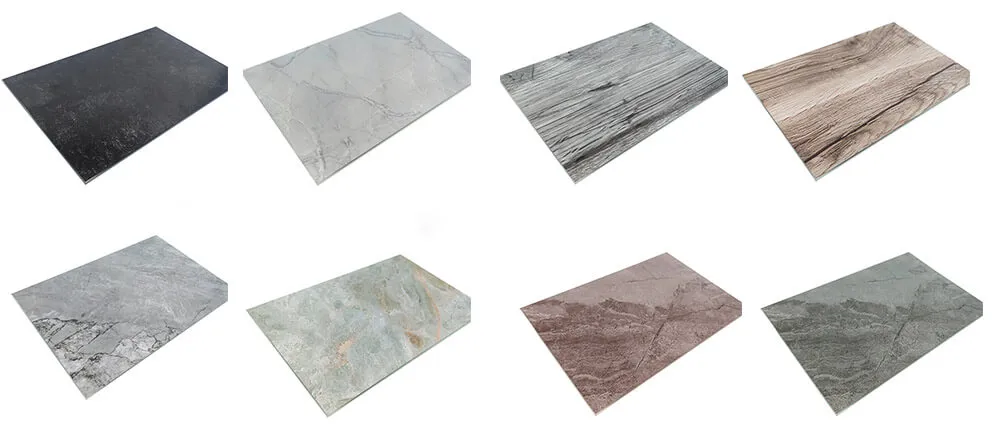

In addition to these popular clear glass dining tables, we also produce high-end faux marble glass dining tables, and the glass used to create these table tops is known as glazed glass.

- Waterproof and anti-corrosion, very durable

- Fire and high-temperature resistance

- Safe, scratch and wear resistant

- Food-grade surface, environment-friendly

- Diamond-grade hardness, super wear-resistant

- High-dense material, 0 penetration

What is stained glaze glass?

The stained glaze is inorganic, printed onto the surface of the glass, then tempered after drying. The glaze is sintered on the surface of the glass to form a decorative glassware product.

Stained glaze glass generally refers to high-temperature glass, and glaze printing needs to sinter at a temperature of 600-700 ℃ on the surface of the glass. The glaze used in colored glazing glass is generally inorganic color and glass with a low melting point. In the process of tempering and sintering, the glaze will fuse to the glass surface, so it has stable color, not easy to fade, and the glaze layer is firm and does not easy to fall off

Features

In theory, digital printing or screen printing can achieve any naturally beautiful pattern you see on the surface of the glass, such as wood grain, marble, granite textures, cement grey effects, etc., which will provide users with more options.

In addition, this high-temperature baked glaze is scratch-resistant, stain-resistant, non-fading, moisture-resistant, and anti-scalding.

DT8858-9 Extendable Glass Table

DT8858-9 Glass Table with Modern Chairs

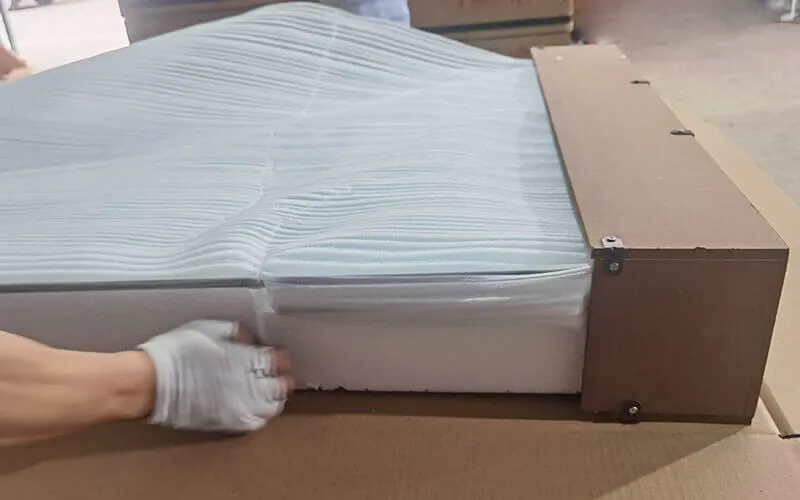

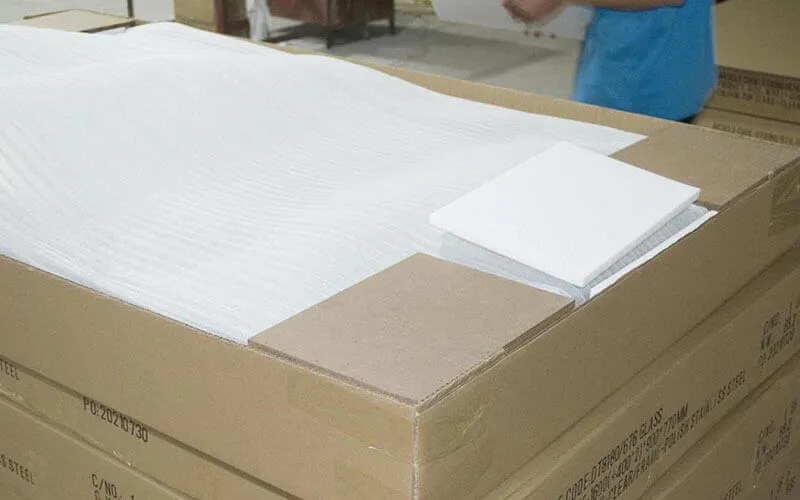

Carefully packed to protect glass tables for safe transport over long distances

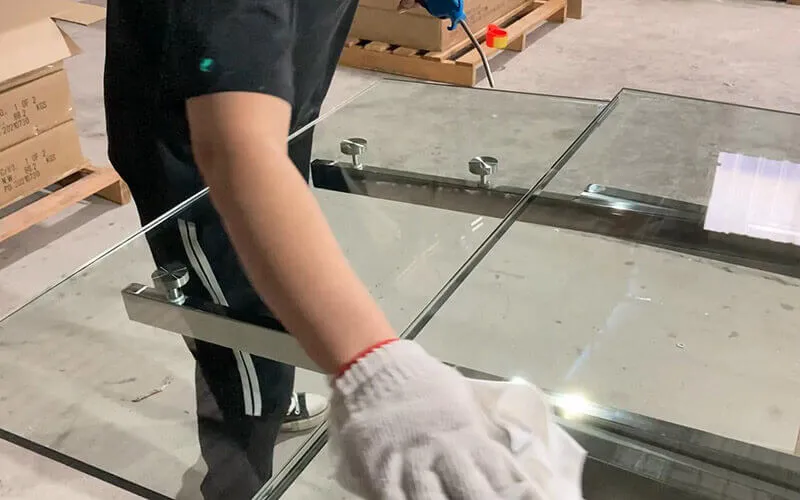

Step 1. Thoroughly clean the tabletop before packing

Step 2. Put EPE between extension leaf & tabletop to buffer

Step 3. Use two MDF Sleeves to protect the tabletop 2 ends

Step 4. Use extensive Foam Inserts to protect tabletop

Step 5. Put lid box onto tabletop

Step 6. Seal the package

Can I buy a piece?

Sorry, in order to keep cost at a reasonably economic level, 20pcs MOQ is needed from we manufacturer, because raw material suppliers require the same or even more quantity to keep their purchasing cost as low as possible.

Is your glass tabletop easy to crack?

No, however, the inherent feature of tempered glass is spontaneous breakage which is about 1~3%.

The impact strength of tempered glass of the same thickness is 3 to 5 times that of ordinary glass, and the bending strength is 3 to 5 times that of ordinary glass. 10,12mm thick qualified tempered glass used as tabletop from us is durable and tough enough for years of use and every glass piece will be carefully packed to guarantee it’s safe enough for long distance transportation.

Are glass tabletops easily scratched?

How to clean a glass table?

How to maintain the table rack hardware?

Even if the so-called stainless steel is used for a long time, it will rust. In order to prolong the service time of the metal dining table, you are suggested to do the following things well

A. Try to avoid putting metal dining furniture in wet places, let alone scrubbing electroplated furniture or metal parts with a wet cloth, which will accelerate metal rust.

B. When a yellowish brown stain is found on the surface of metal furniture, it can be wiped regularly with neutral oil or engine oil to prevent the expansion and the deterioration and rust of the electroplated protective layer.

C. Rust parts shall not be sanded with sandpaper. Apply engine oil evenly on the rusty place. After placing for a period of time, the rust can be wiped off.

Wait! Before you go— Check out our best-selling ceramic tables for a more matte, stone finish.Go to Ceramic Tables

A stunning table deserves the perfect seat. Complete your showroom set with our best-selling chairs. Explore our full Dining Chair Collection